There are a few known methods to join two wires together, but after years of fixing fox body alarm and radio installs and seeing things like solderless twist-on connectors (Marettes) and poorly joined and just taped connections. I thought I’d provide a quick guide to soldering automotive wiring.

A few basics don’ts

- Don’t use solid wire – this is not going to hold up to vibrations.

- Don’t use solderless twist-on connectors.

- Don’t use electrical tape to insulate splices – heat and moisture will degrade the adhesive and the tape can eventually unwind.

Some basic do’s

- Always use same gauge stranded wire that can hold up to automotive use.

- Try and follow the color codes on the factory harness (buying a set of different colored spools helps, I normally have a few EFI scrap harnesses in stock for lengths of wires too).

- Always make sure your splices/connections are well insulated and have strong mechanical bonding.

Polyolefin shrink tubing

Instead of simply using electrical tape to cover your wire joints, use heat shrinking tubing. This material is resistant to flame and abrasions, extremely flexible and has excellent chemical, physical and electrical properties. This will produce a much more reliable join or splice and is highly recommended for professional work.

A quick soldering guide

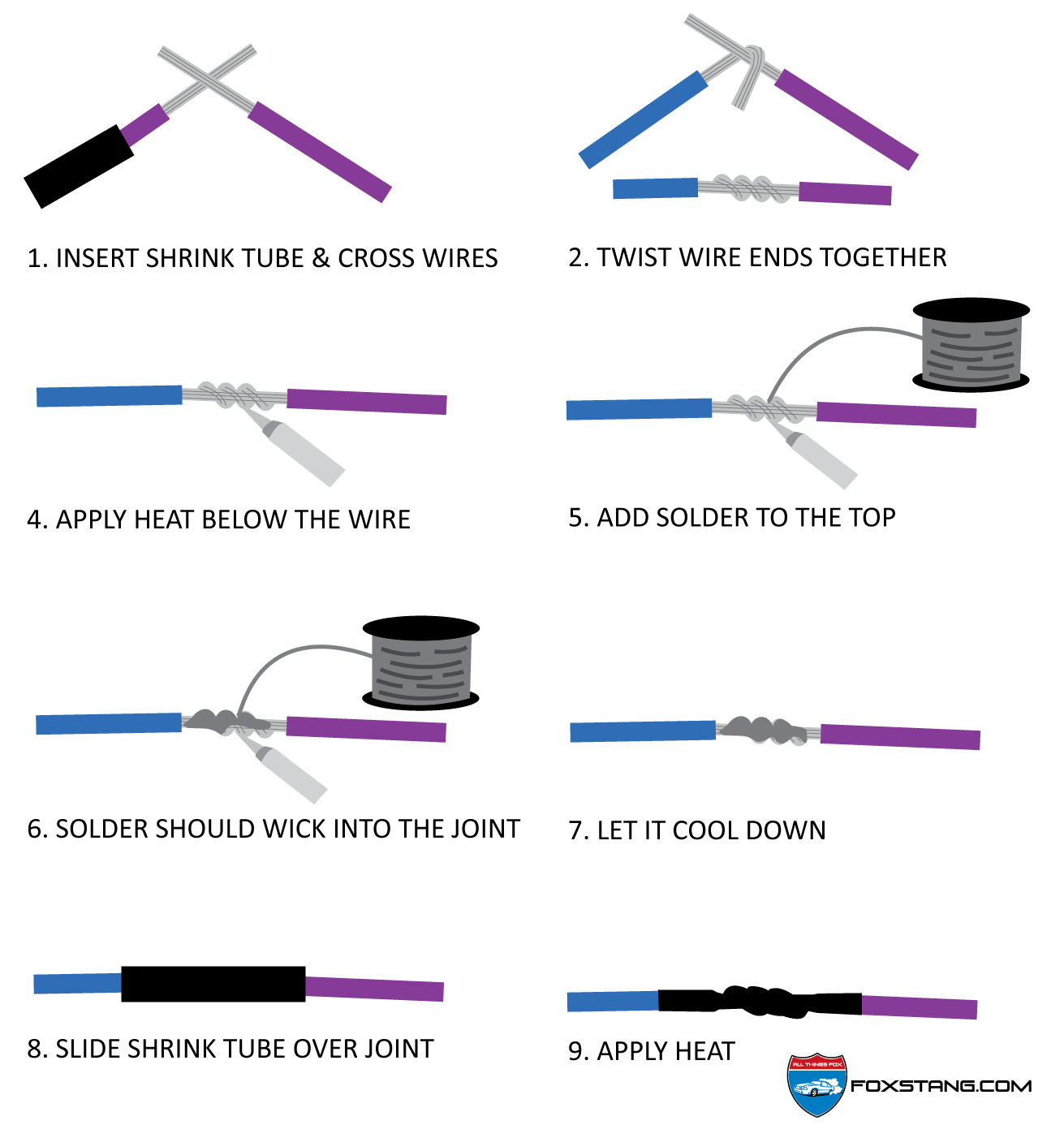

Soldering can be an art-form for some. It’s best to practice on some pieces of scrap wiring. It can also be fun (in a nerdy way) to use an ohmmeter to check the resistance of your splices. Use nothing but 60-40 rosin-core solder intended for electrical wiring. Below is a graphic-guide to soldering wires together. Note: be sure to slip the shrink tubing over the wire before joining them!