Lots of soul searching which brought upon me an existential crises but at the end of the day I finally decided on what electrical fan system to put together.

First, you should know I have a great 3 core aluminium rad and a “pretty much” stock 302 which won’t require as much cooling as a boosted, high power engine. But my cooling system should be able to handle a lot more heat than my little engine can produce.

What fan should I get?

My first question which led to a bleeding ulcer. I settled on an American Made (Canadian Motor) Flex-a-lite (FLX-118). Because it’s a good reliable brand, affordable and pretty small. If you have the budget, one of the best fans is the “Flex-a-lite Black Magic Xtreme Series Electric Fans 188” at 3300 CFM compared to the 118’s 2500. I stayed away from ProForm only because of the reviews but personally I think it would be okay if you have a good rad and mild engine to cool. You could also do a junkyard Mark VIII, Taurus or even SN95 fan (you can still get a new assembly at RockAuto) but that requires some trimming and fitting of the shroud to make it fit on the fox.

Wiring?

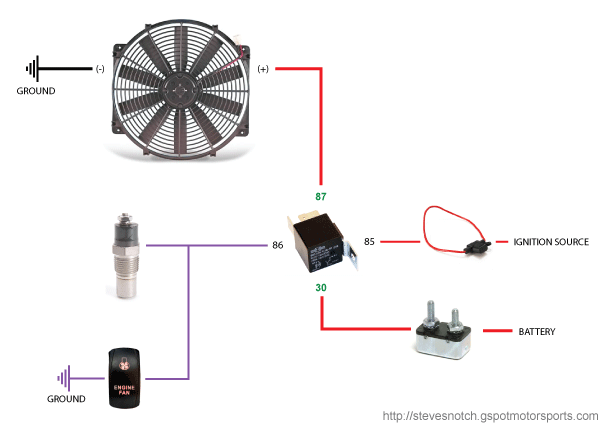

Lots of good and bad ways to do this. Below is a diagram I made to show how I went about it. (Download wiring diagram [PDF format]). Depending on what relay you use, you may want to double check pins 86 and 85, if you’re using a bosch type you could be powering 87 or 87a depending on what polarity is being used on pins 85/86 🙂

Parts List:

1) Electric fan, 2500cfm minimum.

2) 75amp relay (AWW-500532)

3) Thermal Fan Switch (SPU-IX-195TS)

4) 12v switch

5) 12v /50amp circuit breaker (BSS-CBC50HB)

6) Inline fuse for ignition source

7) 12GA wiring (fan)

8) 14GA wiring

9) 2-pin connector for fan harness

You can choose your own fan switch for your desired range and fitment. I didn’t go with a pre-made fan controller, I don’t think there’s a need to continually adjust a controller for on/off temps and prefer to have something simple and reliable which is why I went with a 75amp relay which is much overkill for the little 2500cfm fan I have. Note: If you want to be a relay expert, read this page.

If you want a two speed fan, use two relays (one for each speed) and install another temp sensor (or bypass switch for the 2nd fan). If there’s lots of demand for it, I can make different diagrams.

If you’re running a dual fan setup, just add another relay following the same kind of diagram, just share the sensor/switch circuit and larger wiring from the battery to connect both relays for power (pin 30).

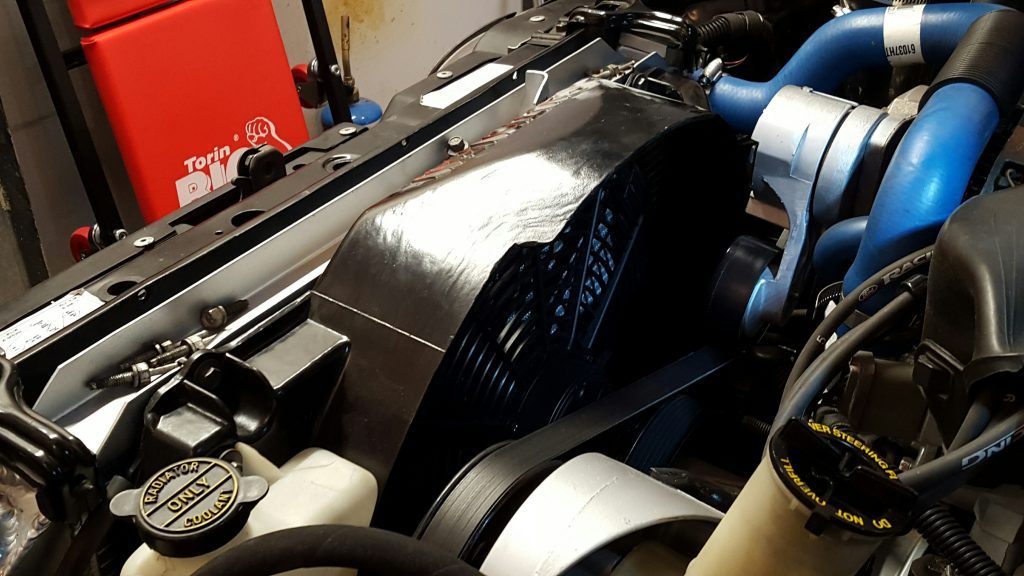

Installing the fan

I wanted to maintain the “stockish look” so I bolted it to the existing shroud. I made a bracket for the bottom (simple flat steel bottom with two pieces welded on to reach the bottom of the fan mounting holes lol mounting holes… giggity). For the top, I just bolted through the top of the shroud, although I’m not happy about seeing these bolts on top of the rad, I’ll either use carriage bolts or think of something. Note that I had to remove the tab from the top of the shroud so the fan can run.

I installed the 195/175 thermal switch, I have a 180 thermostat in the 302 right now. I let it idle for an hour, outside temp was a little over 100F with humidex (I guess that’s a Canadian thing). The fan turned on and off like I expected it to.

See below the semi-finished installation of the fan/shroud assembly.